At Western University’s Faculty of Engineering, University Machine Services (UMS) is helping turn bold ideas into tangible products while also playing a role in strengthening the region’s workforce.

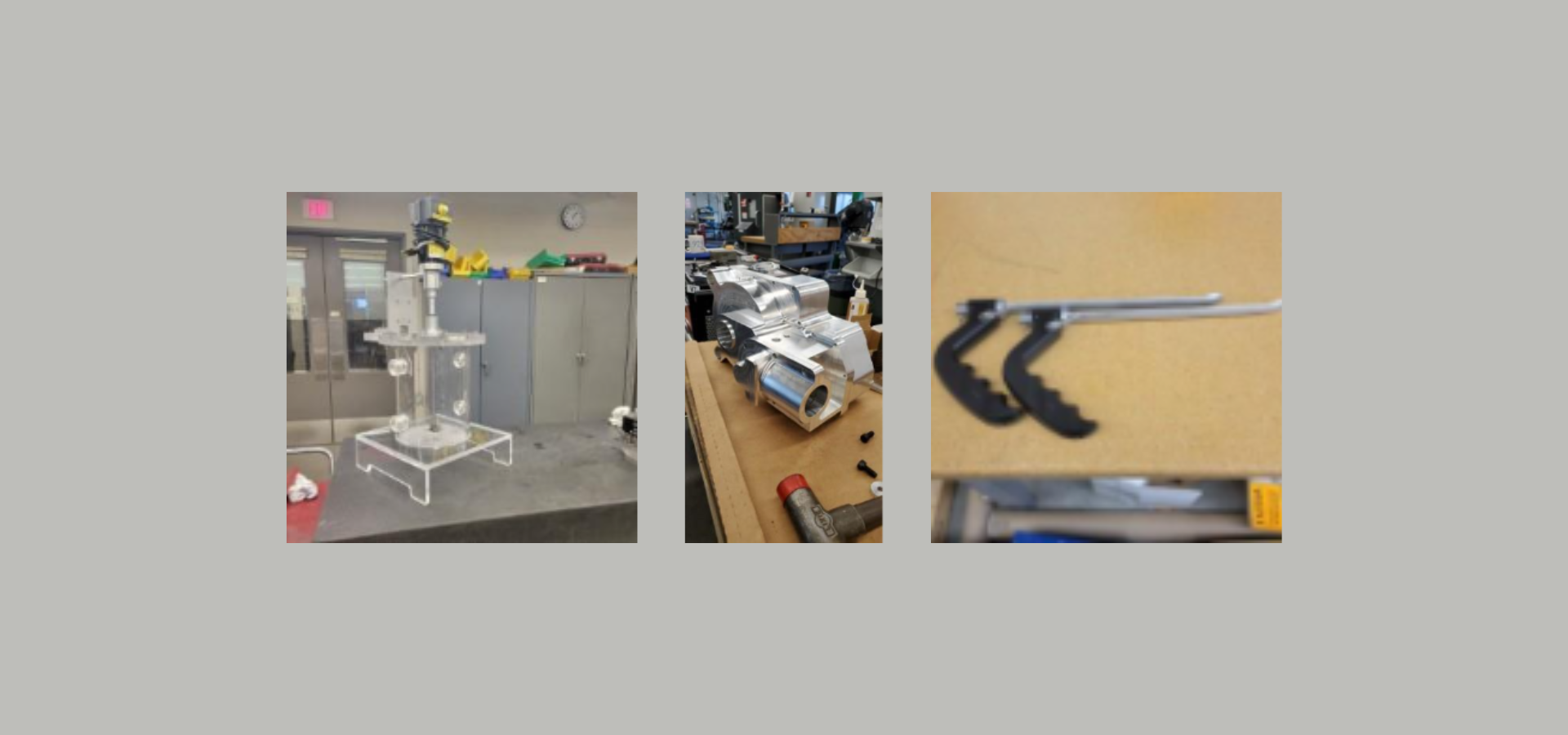

“University Machine Services is a service unit within Western University dedicated to offering a variety of technical solutions,” said Cody Ruthman, laboratory support specialist and project manager at Western Engineering. “Housed in the Thompson Engineering building, we design, develop, manufacture and maintain equipment for research and industry. We are also technical consultants during the planning stage of projects.”

That mix of expertise and infrastructure has made UMS a go-to resource well beyond London. In one example, the team was approached by Exxon Mobil to develop and automate its dewaxing process and manufacture the associated equipment. The systems UMS developed are now in place at refineries worldwide, with the most recent installed at the company’s Singapore facility.

“We engineer, design, and manufacture in-house allowing us to provide the most cost-effective solutions,” Ruthman said. “During every project our team goes the extra mile by advising the client on ways they can reduce their costs at all stages of the project.”

UMS adapts to each client’s needs — whether it’s a start-up founder sketching an idea on a napkin or a corporation supplying detailed CAD files. The process always begins with a conversation to fully assess goals and identify the best path forward, with meetings offered both online and in-person.

Since the 1970s, Western has relied on UMS to help turn cutting-edge research concepts into reality. The unit has produced equipment that supports world-class research, contributing to the university’s reputation as one of Canada’s premier academic institutions. That same innovation translates into industry applications.

“Being on the forefront of research within academia, we can offer novel solutions to industry ensuring the success of their projects,” Ruthman said. “We are an asset to industry by offering different perspectives and our vast amount of technical experience.”

For the LEDC, units like UMS highlight the connection between talent, technology and industry that drives the city’s economy. By working with students and researchers while also serving as a partner to companies, UMS strengthens both workforce development and local competitiveness.

That connection will be on display October 2, when UMS takes part in LEDC’s Manufacturing Matters event. The team will host a booth to showcase its capabilities and connect directly with industry leaders looking for innovative solutions.

UMS leaders say that mindset extends into the future. The unit is constantly exploring new tools and processes, drawing lessons from one industry and applying them to another. That diversity, Ruthman noted, keeps the team sharp and ensures that London-based businesses have access to global best practices.

“UMS is always available to help,” Ruthman said. “From the up-and-coming backyard entrepreneur to the established corporation. Please feel free to contact us and we will turn your ideas into reality.”

Looking ahead, the vision is simple: keep evolving while staying focused on customer success.

“UMS will continue to provide novel solutions to its client’s needs,” Ruthman said. “We will continue to take great strides in ensuring that the customer not only gets what they want, but what they need to be successful.”

With a refreshed website and a renewed commitment to outreach, Western’s University Machine Services is positioning itself as more than just a unit on campus. It’s a bridge between academic research, industry innovation and the skilled workforce that will power the region’s future.

Learn more and contact the team here.